Sterilux Poultry Case Study

Chicken Farm Lighting Upgrade with Sterilux Sanitization LED Bulb

LOCATION

Seremban, Malaysia Farm

FARM TYPE

Commercial Breeder Farm

7,000 chickens

6.2 cycles

DATE

06/23 – 07/30/25

38 days

PREVIOUS

Conventional A60 10W LED Bulbs

UPGRADED

Sterilux Sanitization A60 10W LED Bulbs

Case Study: Sterilux Improves Poultry Health and Food Safety at Poultry Farm

By Herman C.C. — August 5, 2025

Author

Herman C. C.

Issue Date

August 05, 2025

Subject

Optimizing Breeder Farm Performance: Lessons from the Field

Executive Summary

The farm, a 7,000-hen layer operation in Malaysia, faced high mortality rates (~3%) and excessive bacterial contamination on eggs (>18,000 RLU). Within a single production cycle of installing Sterilux photocatalytic lighting, mortality dropped to 1.8%, bacterial loads decreased by more than 90%, and chicken weights increased from 3% to 7%.

These improvements boosted health, lowered stress, increased weight gain, and enhanced farm profitability — all without disrupting daily operations.

Background

The farm supplies fresh eggs to local retailers, where consistent yield and strict food safety compliance are critical for contract fulfillment and customer trust. Before Sterilux adoption, the farm relied on standard A60 10W LED bulbs, which provided adequate illumination but offered no antimicrobial effect.

Despite compliant lighting levels, the farm faced persistent challenges:

Mortality rate: ~3% per cycle (≈210 birds lost per 7,000), well above the 1.5–2% benchmark for commercial layers.

Bacterial contamination: Egg surface swabs routinely exceeded 18,000 RLU (Kikkoman hygiene testing), surpassing Grade A classification thresholds.

These issues increased veterinary costs, risked regulatory non-compliance, and threatened long-term buyer relationships.

Challenges

The farm needed to address two critical pain points that were limiting productivity and profitability:

Excess mortality — losing over 200 birds per 7,000-cycle due to elevated mortality rates, reducing total egg output and inflating veterinary costs.

Excessive bacterial load on eggs — contamination levels frequently exceeding 18,000 RLU, causing egg downgrades, potential contract penalties, and increased food safety risk.

The farm required a cost-effective, low-maintenance solution that could:

Actively reduce bacterial contamination at the source.

Lower mortality without introducing new stressors to the birds.

Integrate into existing infrastructure with minimal operational disruption.

Solution

The Farmarm implemented the Sterilux photocatalytic sterilization lighting system, replacing the existing A60 10W LED bulbs in each poultry house. Unlike conventional lighting, Sterilux fixtures emit visible light in the 450–700 nm range, activating a catalytic membrane coated with nano titanium dioxide, copper ionic components, and silicon dioxide. This process generates reactive oxygen species (ROS), which continuously break down bacteria, viruses, and other pathogens in the illuminated space.

Key implementation details:

Direct replacement: Sterilux units were installed in the same positions as the old bulbs, maintaining optimal light distribution for feeding, egg laying, and worker activities.

Continuous operation: Lights were operated on the farm’s existing day–night cycle, ensuring pathogen control during lit hours without altering bird routines.

No chemical additives: The system provided sterilization without introducing new consumables, residues, or handling requirements.

This approach allowed the farm to address both bacterial contamination and mortality issues at the source — inside the poultry house — while preserving the familiar workflow for staff and birds.

Results

Within the first full production cycle after installing Sterilux, The farm recorded measurable and sustained improvements across key performance metrics:

Mortality reduction: Mortality fell from ~3% to 1.8% per cycle, representing over 80 additional birds surviving per 7,000-cycle and increasing total egg output.

Bacterial load reduction: Egg surface contamination dropped by over 90%, with average swab readings falling from peaks of 18,677 RLU to consistently below 1,500 RLU, meeting Grade A classification standards.

Odor & VOC reduction: Ammonia odors and airborne volatile organic compounds (VOCs) inside the poultry houses decreased noticeably, improving working conditions for staff and reducing respiratory stress factors for the birds.

Operational continuity: Changes were achieved without altering feeding schedules, housing layout, or staffing routines, minimizing training and adaptation time.

These results translated into higher saleable output, lower veterinary costs, and improved environmental conditions, strengthening the farm’s competitive position and long-term buyer relationships.

Impact

Sterilux enabled the poultry farm to:

Improve food safety compliance and maintain retailer contracts.

Increase saleable egg output and profitability.

Reduce veterinary interventions and operational risk.

Enhance worker and animal welfare conditions.

Limitations & Next Steps

This case study represents results from a single pilot farm, without a control barn. Outcomes may vary based on housing design, flock health, and environmental factors.

Next Steps:

Multi-site validation with farms >10,000 layers (Q4 2025).

Publish peer-reviewed data on poultry mortality and food safety outcomes (Q1 2026).

Expand trials with additional poultry producers across Southeast Asia.

About Sterilux

Sterilux develops next-generation photocatalytic sterilization lighting systems that use visible light to continuously reduce bacterial and viral loads in real-world environments. Unlike traditional disinfection methods, Sterilux delivers round-the-clock protection without chemicals, UV, or workflow disruption.

Visuals

Conventional A60 10W LED bulb

18,677 RLU (Kikkoman hygiene reading)

1,328 RLU (Kikkoman hygiene reading)

Sterilux Sanitization LED Bulb

Sterilux Sanitization LED Bulb

Location:

Yong’s Farm Sdn. Bhd. (Seremban, Malaysia)

Farm Type:

Commercial Breeder Farm

7,000 chickens

6.2 cycles

Date:

06/23 – 07/30/25

38 days

Previous Lighting:

Conventional A60 10W LED Bulbs

Upgraded Lighting:

Sterilux Sanitization A60 10W LED Bulbs

Author

Test

Issue Date

Test

Subject

Test

Background

Yong’s Farm operates a multi-tier poultry housing system in [region/country], accommodating approximately 7,000 laying hens per production cycle. The farm supplies fresh eggs to [local retailers / regional distributors], where consistent yield and strict food safety compliance are essential for maintaining contracts and customer trust.

Before implementing any new technology, the farm relied on standard A60 10W LED bulbs throughout its poultry houses. These lights provided adequate brightness for feeding, egg collection, and worker safety but offered no antimicrobial effect. Despite compliant illumination levels, the farm faced persistent and costly challenges:

Mortality rate: averaging around 3% per cycle — significantly higher than the 1.5–2% benchmark for similar commercial layer operations.

Bacterial contamination: egg surface swab tests regularly recorded high readings, with peaks of 18,677 RLU (via Kikkoman hygiene testing), well above thresholds for Grade A classification and food safety guidelines.

These issues not only reduced saleable egg output and farm profitability but also increased veterinary interventions, raised the risk of regulatory non-compliance, and threatened long-term buyer relationships. The farm sought a solution that could simultaneously improve hygiene, reduce mortality, and integrate seamlessly into existing daily operations without disrupting production flow.

Challenges

Yong’s Farm needed to address two critical pain points that were limiting productivity and profitability:

Excess mortality — losing over 200 birds per 7,000-cycle due to elevated mortality rates, reducing total egg output and inflating veterinary costs.

Excessive bacterial load on eggs — contamination levels frequently exceeding 18,000 RLU, causing egg downgrades, potential contract penalties, and increased food safety risk.

The farm required a cost-effective, low-maintenance solution that could:

Actively reduce bacterial contamination at the source.

Lower mortality without introducing new stressors to the birds.

Integrate into existing infrastructure with minimal operational disruption.

Results

Within the first full production cycle after installing Sterilux, Yong’s Farm recorded measurable and sustained improvements across key performance metrics:

Mortality reduction: Mortality fell from ~3% to 1.8% per cycle, representing over 80 additional birds surviving per 7,000-cycle and increasing total egg output.

Bacterial load reduction: Egg surface contamination dropped by over 90%, with average swab readings falling from peaks of 18,677 RLU to consistently below 1,500 RLU, meeting Grade A classification standards.

Odor & VOC reduction: Ammonia odors and airborne volatile organic compounds (VOCs) inside the poultry houses decreased noticeably, improving working conditions for staff and reducing respiratory stress factors for the birds.

Operational continuity: Changes were achieved without altering feeding schedules, housing layout, or staffing routines, minimizing training and adaptation time.

These results translated into higher saleable output, lower veterinary costs, and improved environmental conditions, strengthening the farm’s competitive position and long-term buyer relationships.

Solution

Yong’s Farm implemented the Sterilux photocatalytic sterilization lighting system, replacing the existing A60 10W LED bulbs in each poultry house. Unlike conventional lighting, Sterilux fixtures emit visible light in the 450–700 nm range, activating a catalytic membrane coated with nano titanium dioxide, copper ionic components, and silicon dioxide. This process generates reactive oxygen species (ROS), which continuously break down bacteria, viruses, and other pathogens in the illuminated space.

Key implementation details:

Direct replacement: Sterilux units were installed in the same positions as the old bulbs, maintaining optimal light distribution for feeding, egg laying, and worker activities.

Continuous operation: Lights were operated on the farm’s existing day–night cycle, ensuring pathogen control during lit hours without altering bird routines.

No chemical additives: The system provided sterilization without introducing new consumables, residues, or handling requirements.

This approach allowed the farm to address both bacterial contamination and mortality issues at the source — inside the poultry house — while preserving the familiar workflow for staff and birds.

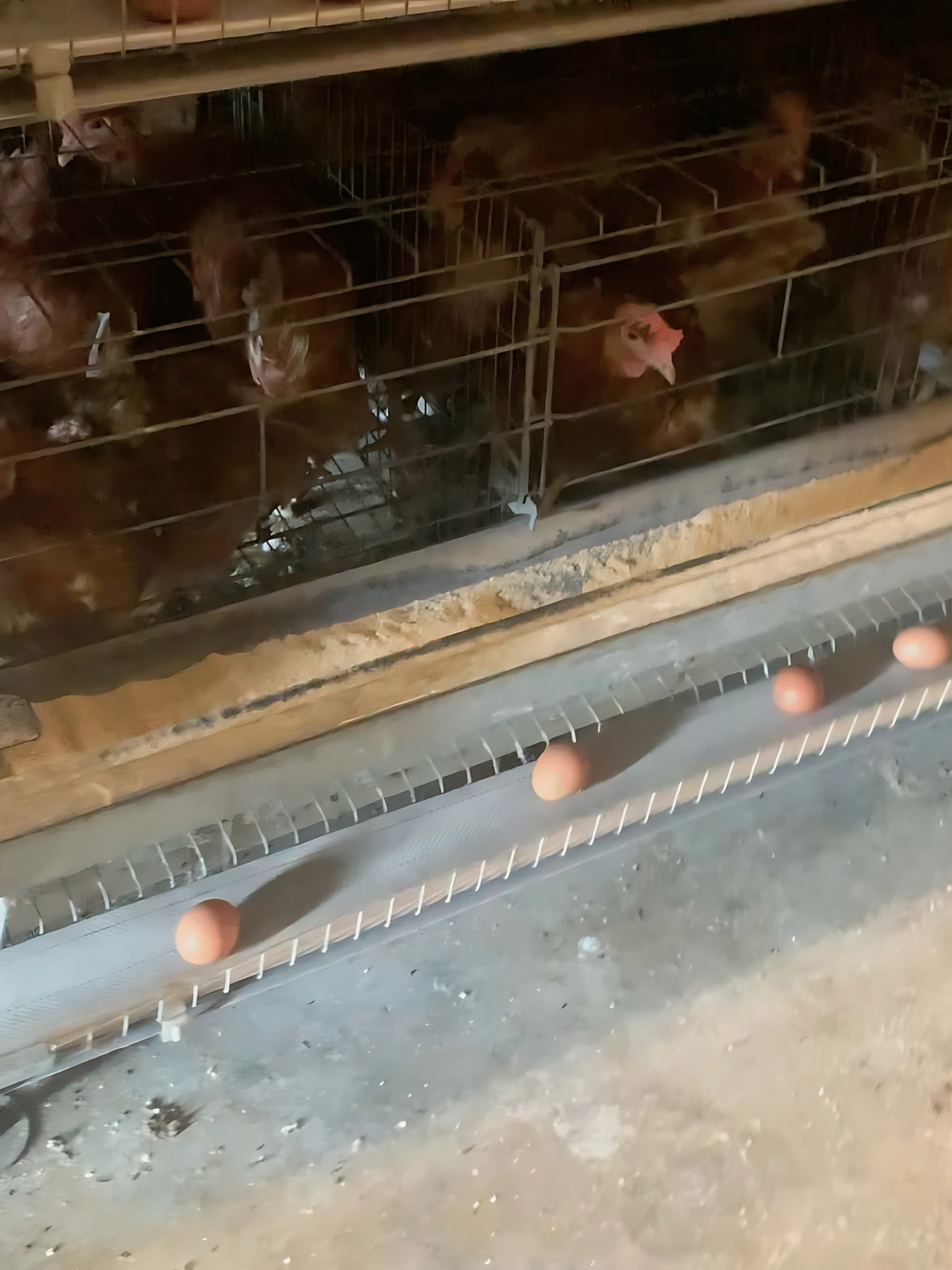

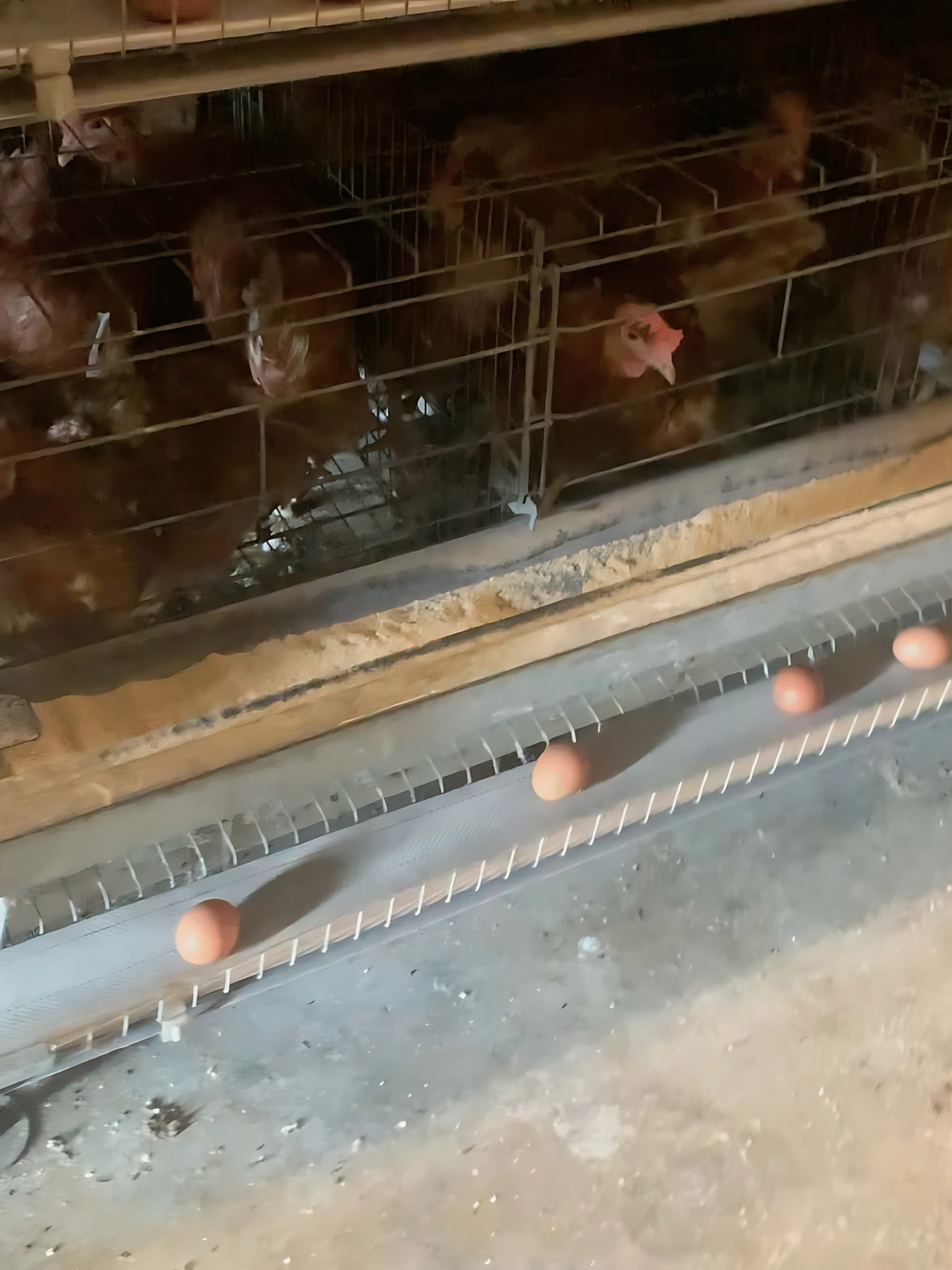

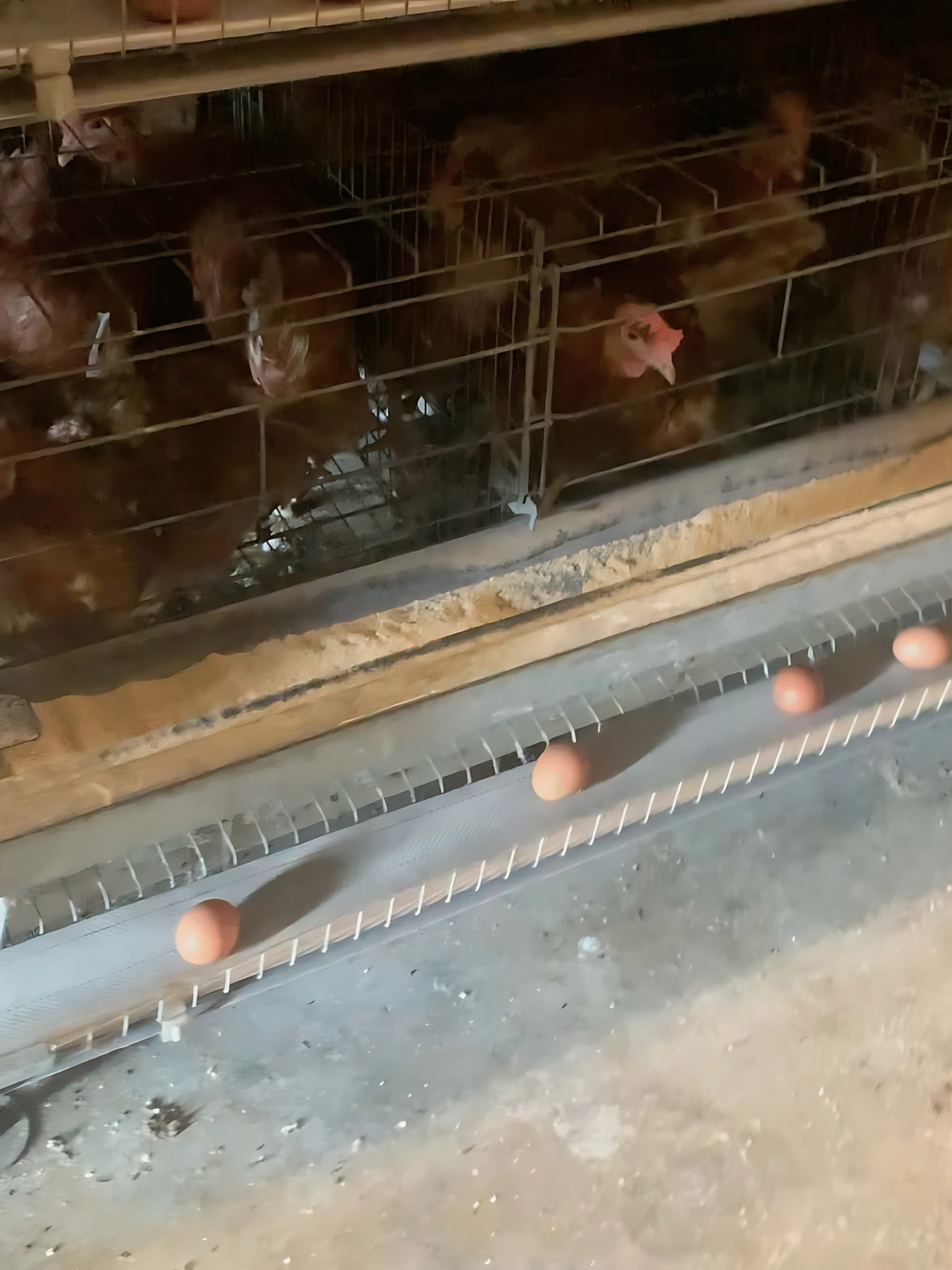

Visual Evidence

Seremban, Negeri Sembllan, Malaysia

Conventional A60 10W LED bulb

18,677 RLU (Kikkoman hygiene reading)

1,328 RLU (Kikkoman hygiene reading)

Sterilux Sanitization LED Bulb

Sterilux Sanitization LED Bulb

Application Case Study

Background

Yong’s Farm operated its poultry houses using standard A60 10W LED bulbs. Despite adequate illumination, the farm experienced persistent challenges:

-

Mortality rate of approximately 3% per chicken cycle.

-

High bacterial contamination on egg surfaces, with readings up to 18,677 RLU (measured via a Kikkoman hygiene testing machine)

Seremban, Negeri Sembllan, Malaysia

Conventional A60 10W LED bulb

18,677 RLU (Kikkoman hygiene reading)

Intervention

At the start of a new production cycle, the farm replaced all existing bulbs with Radiant Sanitization A60 10W LED Bulbs — designed to provide both illumination and antimicrobial benefits for poultry environments.

No other operational changes were made during the trial period, ensuring results reflected lighting impacts alone.

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged. It was popularised in the 1960s with the release of Letraset sheets containing Lorem Ipsum passages, and more recently with desktop publishing software like Aldus PageMaker including versions of Lorem Ipsum.

Sterilux Sanitization LED Bulb

Sterilux Sanitization LED Bulb

Results

-

Reduced Mortality Rate

This represents a two-thirds reduction in chicken deaths per cycle. -

Improved Egg Hygiene

The dramatic 93% drop in bacterial presence indicates a significant reduction in surface contamination risk.

-

Reduced Mortality Rate

This represents a two-thirds reduction in chicken deaths per cycle. -

Improved Egg Hygiene

The dramatic 93% drop in bacterial presence indicates a significant reduction in surface contamination risk.

1,328 RLU (Kikkoman hygiene reading)

Testimonial

“We were surprised by how much impact just changing the lighting had. After using Radiant Sanitization bulbs for one cycle, our chickens were clearly healthier, and the egg hygiene improved drastically. The Kikkoman machine results backed it all up.”

— Liang, Yong’s Farm Sdn. Bhd.

Conclusion

The lighting upgrade at Yong’s Farm demonstrates that Radiant Sanitization LED technology can deliver measurable benefits in commercial poultry farming by:

-

Improving animal survival rates.

-

Enhancing food safety through cleaner eggs.

-

Supporting a healthier farm environment with no other changes to operations

Application Form

Let's Talk!

We’re available for commissions and collaborations, and I’m excited to hear from you