Next-Gen Sterilization

Harnessing Photocatalysis

Discover how Sterilux uses advanced photocatalysis to deliver chemical-free sterilization — a cleaner, safer, and smarter solution for tomorrow’s hygiene challenges.

Photocatalytic Sterilization

Light-Activated Electron Transfer

Sterilux’s system is built on a Quantum Resonance Hybrid Nano Formulation — an engineered reactive nano-layer designed to maximize photoreactivity. When exposed to light, this advanced photocatalytic nano-layer generates reactive oxygen species (ROS) with enhanced range and efficacy.

Our system uses specially tuned SMDs that emit light optimized for photocatalytic activation. When this light passes through our custom-engineered Sterilux Coating, it triggers an advanced sterilization reaction on airborne contaminants.

This enhanced photocatalytic effect extends the sterilization range significantly—reaching up to 12 feet from the source. The result is broader, safer, and more efficient air purification without the need for harsh chemicals or expensive air filtration equipment.

Core Benefits

- Safe for Prolonged Exposure — Proven, and widely adopted

Chemical-Free Operation — No peroxide, ozone, or toxic residue

Safe for Sensitive Surfaces — Electronics, optics, and PPE

No Additional Energy — Sustainable and mobile-ready

No Water Required — Operates dry and clean in any environment

Step-by-Step Reaction Process:

Photon Absorption

Incoming photons — from our custom-tuned LED SMD’s — strike the Quantum Resonance Hybrid Nano Surface, exciting electrons (e⁻) from a lower-energy state to a higher-energy conduction state, leaving behind positively charged holes (h⁺).Charge Carrier Activation

These electron-hole pairs act as redox agents. The electrons reduce ambient oxygen into superoxide radicals (•O₂⁻), while the holes oxidize surface moisture to generate hydroxyl radicals (•OH).Formation of Reactive Oxygen Species (ROS)

These ROS are short-lived but extremely potent — breaking down microbial membranes, disrupting viral envelopes, and degrading nucleic acids with no toxic residue.Pathogen Destruction

ROS immediately attack pathogens at the molecular level, rendering them inactive and non-replicative, all without heat, moisture, or harmful chemicals.Neutral Reversion

Once the reaction completes, the radicals revert to inert byproducts like oxygen and water vapor — leaving the treated environment clean and residue-free.

Why This Matters

The Quantum Resonance Hybrid Nano Formulation solves key challenges in traditional photocatalysis:

1. Extended ROS activity range

2. High photocatalyst reactivity

3. Exceptional membrane stability over time

This breakthrough enables consistent, high-efficacy sterilization in real-world, uncontrolled environments — not just the lab.

Innovation

What Sets Our Technology Apart

For years, photocatalysis was held back by practical limitations — short effective range, inconsistent pathogen kill rates, and surface degradation. Sterilux has solved all three. Our technology is not just novel; it’s now commercially viable.

Sterilization at a Distance

Unlike traditional systems that require extreme proximity to the light source, our devices achieve effective sterilization from significantly farther away — enabling broader coverage per unit and easier integration into real-world spaces.

Consistently High Efficacy

Our photocatalytic reaction consistently destroys viruses, bacteria, and spores with lab-validated kill rates that outperform peroxide-based and UV-only systems, without chemical side effects or residue.

Breakthrough Longevity

Sterilux devices are engineered for long-term photocatalyst durability, resisting fouling and degradation across extended use cycles. This ensures consistent performance without frequent maintenance or surface replacement.

Environmental Impact

Sterilization That Works When the Lights Are On

Sterilux doesn’t add energy, chemicals, or waste to your environment — it simply uses the light that’s already on. With no consumables, no extra power draw, and no maintenance cycles, our technology delivers passive sterilization that’s both effective and sustainable.

No Additional Energy Use

Our system leverages ambient light already used for illumination. There’s no separate heating element, no chemical activation, and no energy spikes — sterilization occurs passively when the lights are on.

Zero Waste Operation

No hydrogen peroxide, no ozone, and no chemical cartridges to refill or dispose of. The process produces only water vapor and oxygen as byproducts.

No Special Maintenance

The photocatalytic surface is engineered for long-term durability with no cleaning cycles, replacements, or calibration. It functions continuously and invisibly — no downtime, no hassle.

Carbon-Minimized Design

With no moving parts and no additional energy consumption, Sterilux systems drastically reduce the carbon footprint of traditional sterilization infrastructure.

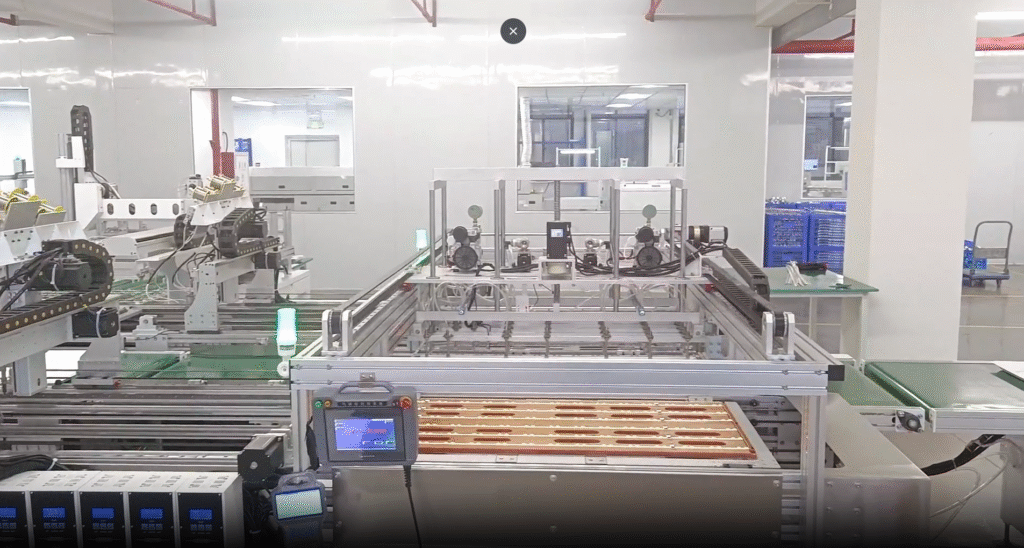

Precision Manufacturing

Cleaner Air for Everyone

Sterilux uses a photocatalytic process that’s grounded in decades of scientific research and widely adopted in fields like environmental purification, healthcare coatings, and air sanitation. We’ve adapted this chemistry for continuous operation — designed specifically for occupied spaces and real-world variability.

Safe for People and Continuous Use

Sterilux produces short-lived reactive oxygen species (ROS) — powerful enough to neutralize pathogens, yet safe for people, animals, and daily exposure. There’s no UV-C radiation, no ozone, and no chemical fogging involved.

No Byproducts, No Cleanup

The reaction returns to oxygen and water vapor, leaving behind no residue, no irritants, and no waste — even in enclosed or poorly ventilated rooms.

Trusted Technology, Refined for Modern Spaces

Photocatalytic systems have been used safely in medical air filtration, consumer hygiene products, and self-cleaning materials. Sterilux builds on this foundation with a formulation that works on surfaces, in air, and under ambient light — without compromising material or human safety.

Electronics & Sensitive Equipment Friendly

Because it requires no moisture, no corrosive agents, and no elevated heat, our system is ideal for environments with electronics, optics, PPE, and delicate tools.

Optimal Performance

>39fc/420lux

Sterilux-enabled lighting installs just like any other lighting fixture/bulb — no special hardware, no custom wiring, no additional labor. The only performance requirement is light level: ensure that target surfaces receive at least 39 foot-candles to activate the full sanitization efficacy.

💡 Light Intensity

Disinfection requires sufficient light (i.e., photon energy) to be activated. Below optimal levels (e.g., 39 foot-candles / ~420 lux), performance decreases significantly, as fewer reactive oxygen species (ROS) are generated.

⏱ Exposure Time

Disinfection is a function of both light intensity and duration. Short exposure times—due to rapid airflow or limited surface contact—can reduce overall effectiveness unless compensated by higher intensity.

🌡 Environmental Conditions

Factors like humidity and temperature affect radical generation. For example, dry air may limit hydroxyl radical production, while extremely hot temperatures can affect catalyst stability or reaction efficiency.

🧪 Product Wear or Fouling

Over time, lenses can become blocked by dust, organic matter, or byproduct buildup, reducing activity. Routine cleaning and maintenance may be required.

How to Use IES Files for Photometric Planning

IES files are digital profiles that describe how light is distributed from a specific fixture. They’re essential for planning lighting layouts in architectural, commercial, or industrial spaces.

To perform a photometric analysis using an IES file:

Download the IES file for the product you’re evaluating.

Import it into lighting design software such as AGi32, DIALux, or Visual Lighting.

Place the fixture in your virtual space, adjusting height, angle, and spacing as needed.

Run simulations to visualize light distribution, measure foot-candle levels, and verify compliance with lighting standards (e.g., IESNA, DLC).

Review the results, including beam spread, uniformity, and brightness to ensure the product fits your application.

Applications

From hospitals to homes, we protect every environment.

Solutions Comparison

Our Latest News

Clients Love

Testimonial

The Technology

Tested, Patented, and Certified

Get Updates

Sign up to receive investor-focused updates, including new product releases, emerging applications across key industries, and exclusive insights into the technologies we're developing at Sterilux. From healthcare and food supply to schools and smart infrastructure, we’re expanding our impact—and we’d love to keep you in the loop as we grow.

Be among the first to hear about strategic milestones, pilot launches, and partnership opportunities.

|

|

Thank you for Signing Up |